Critical to the Consumer Products industry is quality assurance. Our vast product offering allows our customers to have solutions for all their testing applications. We offer pre-engineered and custom component testing chambers along with many patented chamber and airflow designs to meet all Consumer Products industry testing standards.

Our Consumer Products component test chambers can be used to assess almost all Consumer Products. products, equipment and components:

- Packaging

- Food & Beverage

- Apparel

- Electronics

- Health & Beauty Care Products

Our testing systems and environmental simulation chambers offer many options to meet your exact testing requirements.

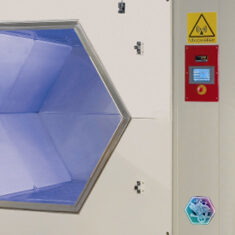

Shelf Life: The stability of chemical, and physical characteristics of Consumer Products are tested after exposure to temperature and humidity. Also, our extremely accurate and reliable stability test chambers are specifically designed to meet many industry requirements.

Climate: Our test chambers can simulate extreme climates to assess the integrity of products and packaging.

Temperature & Humidity: We offer many sizes of chambers that best fit your testing applications for temperature and humidity conditions.

Dust: We inject compressed air through special nozzles and add dust to create a swirl.

Vibration: Our equipment measures the stress on Consumer Products caused by intense vibrations.