Weiss Technik’s battery testing equipment and battery testing systems ensure your products meet or exceed a long list of international standards and norms. Our test chambers can measure the safety, performance and reliability of batteries based on standards established by the International Electrotechnical Commission and other international manufacturing associations. We also can test, measure and assess products based on the exacting and stringent requirements requested by the client.

- ATEX

- DIN Standards

- IEC Standards

- IDC Standards

- IPC Standards

- IEEE

- MIL STD

- EUCAR

Batteries come in many shapes and sizes: miniature cells used to power hearing aids and wristwatches; small, thin cells used in smartphones; large lead acid batteries or lithium-ion batteries in vehicles; and huge battery banks the size of rooms that provide standby or emergency power for telephone exchanges and computer data centers.

Our large selection of tried and tested standard test chambers can handle any sized battery you have. We also will gladly customize our test chambers to fit your exact needs.

Our battery and battery component test chambers can be used to assess almost all batteries and battery applications:

- Electric vehicles

- Power supply

- Switches

- Computers

- Cell phones

- Smartphones

- Tablets

- Medical Devices

- LCD displays

- Data storage

- Appliance controls

- Industrial robotics

- Televisions

- Stereos

- Radios

- Hearing aids

To make sure batteries can provide the power you need, we put them through their paces.

Weiss Technik manufactures battery testing equipment and battery testing systems that simulate a wide variety of environmental influences under accelerated conditions. Whether hot or cold, damp or dry, dusty or wet, at rest or in motion – our test systems cover virtually all conditions:

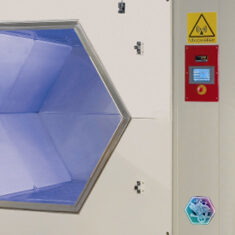

Temperature: Our temperature shock test chamber assesses the effects of extremely rapid temperature changes ranging from -80 °C to +220 °C

Humidity: Our Temperature Humidity Test Chambers can reach 98% humidity (RH) at 95 degrees C.

Tensile strength: We can ensure the quality of materials and integrity of design and construction under realistic conditions.

Dust: We inject compressed air through special nozzles and add dust to create a swirl.

Water splash: To determine if housings are protected from water entering.

Vibration: Our equipment measures the stress on parts caused by intense vibrations during use.

Altitude: Our test chambers can simulate heights of up to 100,000 feet for use of batteries used in aerospace and aviation.

Vacuum: Our thermal vacuum chambers accurately reproduce outer space conditions for pressure, cold, solar radiation, UV and cosmic rays.

Stress: Our Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) tests identify hidden weaknesses and flaws in components.