Quality assurance is critical to the defense and military industries. Weiss Technik’s military and defensive equipment testing equipment and testing systems ensure your products meet or exceed exacting military specifications and other international standards and norms. We also can test, measure and assess products based on the exacting and stringent requirements requested by the military and defense contractors.

- MIL-STD 810

- MIL-STD 883

- DIN Standards

- IEC Standards

- IDC Standards

- IPC Standards

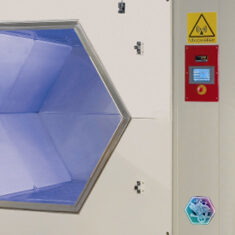

Military vehicles, vessels and equipment, along with each individual part and component, must function effectively and efficiently under extreme conditions. Our military and defense equipment test chambers ensure that entire vehicles and vessels, along with intricate control systems and essential components, can withstand strong vibrations, extreme temperature fluctuations and vacuum conditions.

Our military and defense test chambers can be used to assess almost all military and defense equipment:

- Rockets

- Missiles

- Aircraft

- Helicopters

- Tanks

- Satellites

- Avionics

- Electronics

- Flight control systems

- Communication systems

- Navigation systems

- Weather systems

- Land vehicles

- Personnel carriers

- Armored vehicles

- Ammunition

- Artillery

- Heavy machinery

- Engines

- Landing gear

- Naval landing craft

Ideally, your military equipment never sees action. But to ensure peace, weapons of war must be ready to go to battle at any time at almost any place.

Weiss Technik’s defense and military test chambers and test equipment precisely simulate rough environments, extreme altitudes, and radical temperature fluctuations found during training and combat. Tanks and armored vehicles must operate smoothly and safely in the roughest terrain. Rockets and missiles must withstand rapidly changing temperatures and the potentially detrimental effects of solar radiation, UV rays and cosmic rays. Airplanes and helicopters must endure intense vibrations caused by jet engines, propellers and rotor blades

Our defense and military test chambers and test equipment accurately simulate:

Altitude: Our test chambers can simulate heights of up to 100,000 feet.

Vacuum: Our thermal vacuum chambers accurately reproduce outer space conditions for pressure, cold, solar radiation, UV and cosmic rays.

Vibration: Our equipment measures the stress on engines, rotor blades and spacecraft caused by intense vibrations during take-offs and landings.

Stress: Our Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) tests identify hidden weaknesses and flaws in components.

Fluid change: During flight, the properties of the kerosene can change, leading to malfunctions. Our solutions test your equipment with preheated or cooled kerosene to determine possible problems.

Climate: From the hottest desert to the deepest Arctic freeze. Our automotive and vehicle test chambers are harder than nature, using technology to simulate the widest range of climate around the world in time lapse.

Corrosion: Road salt in winter, salty air or seawater. Everywhere and in all seasons, vehicles are subjected to corrosive conditions. Our test chambers can measure how corrosion affects base metals, highly-alloyed, tempered materials, plastics and painted surfaces.

Seals: Test complete vehicles for proper, leak-proof sealing under reproducible conditions, from drizzle to heavy rain.

Sunlight: Our special test cabinets can simulate the effect of sunlight on the ageing processes in an extensive range of materials.

Vibration: Our equipment measures the stress on engines and body parts caused by intense vibrations while on the road.

Temperature change: Our temperature shock test chamber assesses the effects of extremely rapid temperature changes ranging from -80 °C to +220 °C

Humidity: Our Temperature Humidity Test Chambers can reach 98% humidity (RH) at 95 degrees C.

Tensile strength: We can ensure the quality of materials under realistic conditions.

Dust: We inject compressed air through special nozzles and add dust to create a swirl.

Engine Cooling: We can precisely simulate the entire field of air and liquids to test charging air, engine fluid, gearbox oil and coolant.