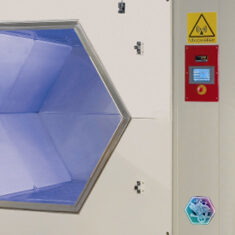

Weiss Technik has a strong presence in the ophthalmic industry, providing customized thermal processing solutions and supplying over 300 ovens to various locations worldwide. Our ovens are designed to meet the stringent requirements of the ophthalmic industry, offering uniform temperature control, airflow, and gas-tight designs to exceed customer expectations. With our expertise, we guarantee reliable and uninterrupted production for manufacturers globally.

Thermal processing is a critical step in manufacturing intraocular and contact lenses. This process is essential for curing and sterilizing these products, ensuring uniform heating and achieving specific chemical properties.

As the market leader for thermal processing in the ophthalmic industry, we plan, develop, and produce customized industrial ovens and oven systems for all thermal processing needs.