Weiss Technik’s solar testing equipment and test chambers ensure your solar panels, solar panel components and solar power generation equipment meet or exceed a long list of international standards and norms. We also can test, measure and assess products based on the exacting and stringent requirements requested by the client.

- IEC 61215

- IEC 61646

- IEC 61730

- IEC 62108

- UL1703

- GB19064

- ASTM E1171

Our solar panel test chambers and testing equipment can be used to assess all parts of your solar panels and solar power generation equipment:

- Solar Panels

- PV Cells

- Aluminum Frames

- EVA Film

- Solar Array Mounting Racks

- Inverters

- Charge Controllers

- Optimizers

- Connectors

- Power Meters

- Generators

- Breaker Panels

- Batteries

- Charge Controller Automotive Products

- Aerospace Products

- Electronics

Before your solar panels can harness the power of the sun, we make sure they’re up to the task.

Weiss Technik manufactures solar testing equipment and test chambers that simulate a wide variety of environmental influences under accelerated conditions. Whether hot or cold, damp or dry, dusty or wet, at rest or in motion – our test systems cover virtually all conditions:

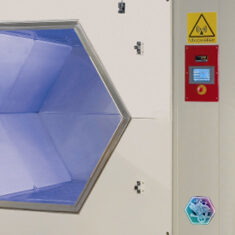

Sunlight: Our Solar Simulation Chambers simulate the effect of sunlight, temperature, and humidity on the properties and the service life of your products. Our special test cabinets also can assess the effect of sunlight on the ageing processes in an extensive range of materials and products.

Humidity: Our Temperature Humidity Test Chambers can reach 98% humidity (RH) at 95 degrees C.

Temperature: Our temperature shock test chamber assesses the effects of extremely rapid temperature changes ranging from -80 °C to +220 °C

Weathering: From the hottest desert to the deepest Arctic freeze. Our solar test equipment and test chambers are harder than nature, using technology to simulate the widest range of climate around the world in time lapse.

Corrosion: Our test chambers can measure how corrosion affects base metals, highly-alloyed, tempered materials, plastics and painted surfaces.

Tensile strength: We can ensure the quality of materials and integrity of design and construction under realistic conditions.

Vibration: Our equipment measures the stress on parts caused by intense vibrations during use.

Stress: Our Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) tests identify hidden weaknesses and flaws in components.