Critical to the electronics industry is quality assurance. Our vast product offering allows our customers to have solutions for all their testing applications. We offer pre-engineered and custom electronic component testing chambers along with many patented chamber and airflow designs to meet all electronics industry testing standards.

Our electronic component test chambers can be used to assess almost all electronic equipment and components:

- Sensors

- Power supply

- Switches

- Computers

- Cell phones

- Tablets

- Medical Devices

- LCD displays

- Data storage

- Appliance controls

- HVAC Controls

- Industrial robotics

- DVD players

- Televisions

- Stereos

- Radios

- Compact disc players

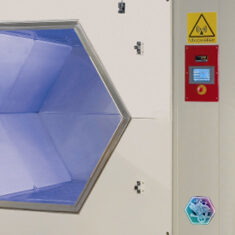

Weiss Technik manufactures electronic component test chambers that simulate a wide variety of environmental influences under accelerated conditions. As a pioneer of testing systems and environmental simulation, we offer customized test systems for the electronics industry that simulate all types of conditions:

Temperature: Our temperature shock test chamber assesses the effects of extremely rapid temperature changes ranging from -80 °C to +220 °C

Humidity: Our Temperature Humidity Test Chambers can reach 98% humidity (RH) at 95 degrees C.

Tensile strength: We can ensure the quality of materials and integrity of design and construction under realistic conditions.

Dust: We inject compressed air through special nozzles and add dust to create a swirl.

Water splash: To determine if housings are protected from water entering.

Vibration: Our equipment measures the stress on parts caused by intense vibrations during use.

Altitude: Our test chambers can simulate heights of up to 100,000 feet for use of electronics components used in aerospace and aviation.

Vacuum: Our thermal vacuum chambers accurately reproduce outer space conditions for pressure, cold, solar radiation, UV and cosmic rays.

Stress: Our Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) tests identify hidden weaknesses and flaws in components.

Lithium-ion: Lithium-ion batteries are the most important source of energy for many electronic devices and must work perfectly, regardless of wind or weather. Our lithium-ion test chambers, you can perform temperature tests, climatic tests, vibration tests, and temperature shock tests.