Weiss Technik’s automotive and vehicle test chambers ensure your products meet or exceed a long list of international standards and norms used extensively by the automotive industry. Our test chambers measure the safety, performance and reliability of products based on standards established by the UCAR Standards and other international manufacturing associations. We also can test, measure and assess products based on the exacting and stringent requirements requested by the client.

Our automotive and vehicle test chambers meet standards such as:

- EPA

- SFTP

- FTP-75

- UDDS

- NYCC

- ECE 15

- EUDC

- UCAR Standard 1703

- ASTM

- DIN

- ISO

- ATEX

- prEN

- Specific automotive company standards such as GM, BMW, Nissan and others

Individual components, integrated systems and entire vehicles all must be tested to ensure they operate safely at all times under all conditions.

Our automotive and vehicle test chambers can be used to assess almost all automotive equipment and components:

- Sedans

- SUVs

- Mini-vans

- Self-driving vehicles

- High-performance race cars

- Trucks

- Agricultural equipment

- Composite body parts

- Batteries

- Suspension

- Engines

- Windows

- Steering

- Fuel pumps

- Fuel and gas tank assembly

- Seats

- Brake systems

- Doors

- Springs

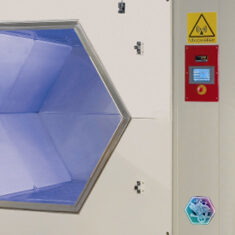

Weiss Technik’s high-quality automotive and vehicle test chambers accurately simulate radical temperature fluctuations, intense vibrations, harsh precipitation, and other conditions that vehicles and automotive components must withstand:

Climate: From the hottest desert to the deepest Arctic freeze. Our automotive and vehicle test chambers are harder than nature, using technology to simulate the widest range of climate around the world in time lapse.

Corrosion: Road salt in winter, salty air or seawater. Everywhere and in all seasons, vehicles are subjected to corrosive conditions. Our test chambers can measure how corrosion affects base metals, highly-alloyed, tempered materials, plastics and painted surfaces.

Seals: Test complete vehicles for proper, leak-proof sealing under reproducible conditions, from drizzle to heavy rain.

Sunlight: Our special test cabinets can simulate the effect of sunlight on the ageing processes in an extensive range of materials.

Vibration: Our equipment measures the stress on engines and body parts caused by intense vibrations while on the road.

Temperature change: Our temperature shock test chamber assesses the effects of extremely rapid temperature changes ranging from -80 °C to +220 °C

Humidity: Our Temperature Humidity Test Chambers can reach 98% humidity (RH) at 95 degrees C.

Tensile strength: We can ensure the quality of materials under realistic conditions.

Dust: We inject compressed air through special nozzles and add dust to create a swirl.

Engine Cooling: We can precisely simulate the entire field of air and liquids to test charging air, engine fluid, gearbox oil and coolant.

Emissions: Make sure your vehicle can any federal or state emissions standards.