Weiss Technik’s aerospace test chambers and space test chambers ensure your products meet or exceed a long list of international standards and norms used extensively by the aerospace industry. Our test chambers measure the safety, performance and reliability of products based on standards established by the Department of Defense, the International Electrotechnical Commission and other international manufacturing associations. We also can test, measure and assess products based on the exacting and stringent requirements requested by the client.

Our aerospace test chambers and space test chambers meet standards such as:

- IEC 60068

- RTCA DO160

- MIL-STD-810

- MIL-STD- 883

- DIN 75220

- PV 1211

- PR 306.4

- DIN 72300-4

Each and every part of a rocket, satellite, airplane or helicopter must function effectively and efficiently under extreme conditions. Our aerospace test chambers and space test chambers ensure that the intricate control systems and essential avionics components can withstand strong vibrations, extreme temperature fluctuations and vacuum conditions.

Our aerospace test chambers and space test chambers can be used to assess almost all aerospace equipment and components:

- Rockets

- Airplanes

- Helicopters

- Satellites

- Avionics

- Flight control systems

- Communication systems

- Navigation systems

- Weather systems

- Fasteners

- Connectors

- Engine components

- Heat exchangers

- Collision avoidance systems

To be safe in the sky, test on the ground.

Weiss Technik’s aerospace test chambers and space test chambers meticulously simulate extreme altitudes, radical temperature fluctuations and intense pressure loads found in outer space. Aerospace components must operate smoothly and safely miles above the Earth. Rockets and satellites must withstand rapidly changing temperatures and the potentially detrimental effects of solar radiation, UV rays and cosmic rays. Airplanes and helicopters must endure intense vibrations caused by jet engines, propellers and rotor blades.

Our aerospace test chambers and space test chambers accurately simulate:

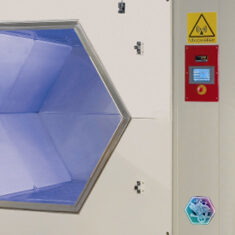

Temperature: Our liquid nitrogen cooling system allows a very precise temperature adjustment, from –185°C to +200 °C. We can also test for rapid temperature changes of up to 30 K/minute.

Humidity: Our Temperature Humidity Test Chambers can reach 98% humidity (RH) at 95 degrees C.

Altitude: Our test chambers can simulate heights of up to 100,000 feet.

Vacuum: Our thermal vacuum chambers accurately reproduce outer space conditions for pressure, cold, solar radiation, UV and cosmic rays.

Vibration: Our equipment measures the stress on engines, rotor blades and spacecraft caused by intense vibrations during take-offs and landings.

Stress: Our Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) tests identify hidden weaknesses and flaws in components.

Fluid change: During flight, the properties of the kerosene can change, leading to malfunctions. Our solutions test your equipment with preheated or cooled kerosene to determine possible problems.