Specifications

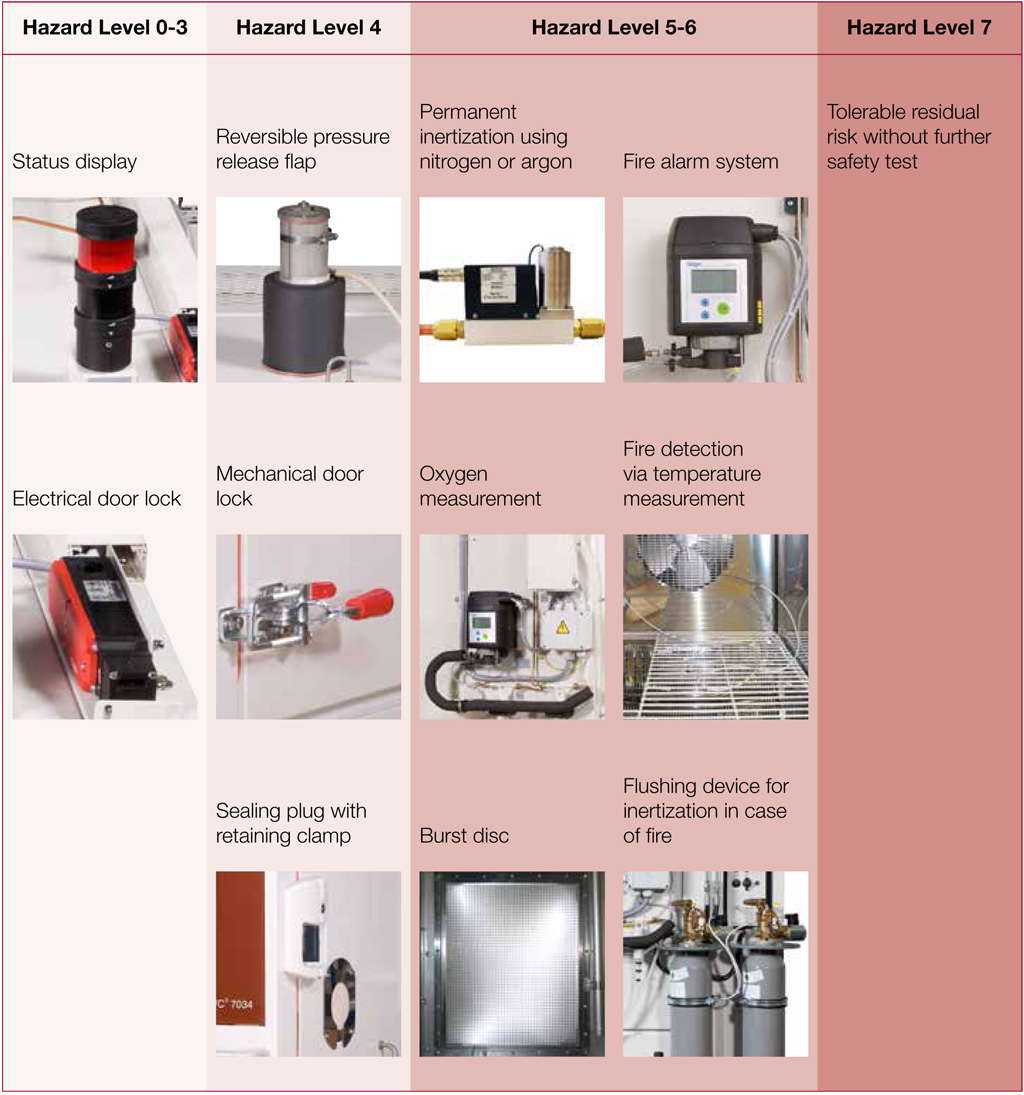

Our test chambers are designed to meet a variety of test standards for safe and reliable testing. To assure this safety in your laboratory during tests with lithium batteries in a temperature- or humidity test chamber, we offer safety features, which are adjusted to the specific EUCAR Hazard Level. Of course, the safety equipment can be adapted individually, according to customer specifications. Please contact us for more detailed information.

| Hazard Severity Level | Description | Classification Criteria and Effect |

| 0 | No Effect | No effect. No loss of functionality |

| 1 | Passive Protection Activated | No defect; no leakage; no venting, fire, or flame; no rupture; no explosion; no exothermic reaction or thermal runaway. Cell reversibly damaged. Repair of protection device needed. |

| 2 | Defect/Damage | No leakage; no venting, fire, or flame; no rupture; no explosion; no exothermic reaction or thermal runaway. Cell irreversibly damaged. Repair needed. |

| 3 | Minor Leakage | No venting, fire, or flame*; no rupture; no explosion. Weight loss |

| 4 | Major Leakage/ Venting | No fire or flame; no rupture; no explosion. Weight loss ≥50% of electrolyte weight (electrolyte = solvent + salt). |

| 5 | Fire or Flame | No rupture; no explosion (i.e., no flying parts). |

| 6 | Rupture | No explosion, but flying parts of the active mass |

| 7 | Explosion | Explosion (i.e., disintegration of the cell). |

Safety in the laboratory and protection of the staff

During the temperature tests, overchargings or malfunctions of the batteries may occur. This can lead to the destruction of the batteries.

Increasing storage sizes cause increasing impacts of possible failures and potential risks during tests with lithium batteries. For this reason, safety in the laboratory, in particular the protection of the staff, during such tests has the highest priority.

To assure this safety in your laboratory during tests with lithium batteries in a temperature- or climatic test chamber, we can offer safety devices, which are adjusted to the EUCAR Hazard Level at an optimum. Of course, the safety equipment can be adapted individually, according to customer specifications. Please contact us for more detailed information