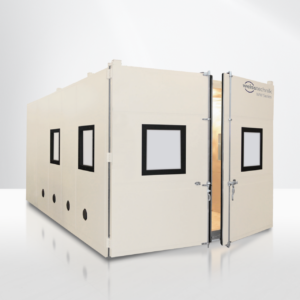

Weiss Technik’s Walk-In Corrosion Test Chambers provide a comprehensive solution for evaluating corrosion resistance under precisely controlled environmental conditions. Designed for industries like automotive and aerospace, these testing chambers simulate harsh environments including salt spray, high humidity, and temperature variations to rigorously assess how materials and components withstand corrosive influences. The SC 1000/15-60 and SC 2400/15-60 IU models meet multiple international testing standards, including ASTM, Mil-Std, and DIN specifications.

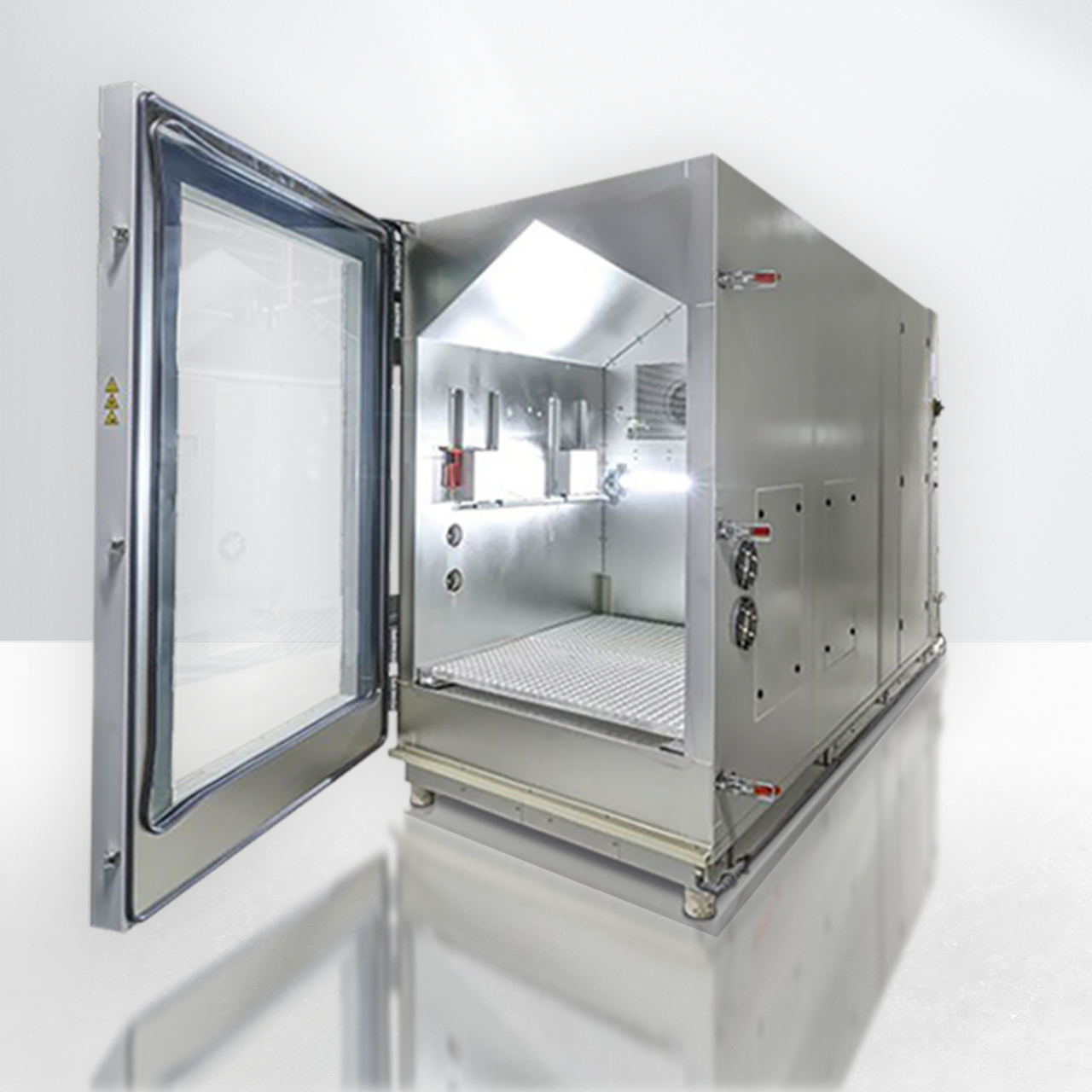

These advanced salt spray corrosion chambers can test a wide range of materials, from base metals to plastics and painted surfaces, simulating complex atmospheric conditions like salty air and seawater. With an optional glass door for continuous monitoring and the ability to perform corrosion alternating tests, Weiss Technik’s Walk-In Corrosion Test Chambers deliver reproducible, certified testing under accelerated conditions, helping manufacturers ensure product durability and safety across diverse industrial applications.

Why Choose Walk-In Corrosion Test Chambers?

- SC 1000/15-60 and SC 2400/15-60 IU models meet multiple international testing standards including ASTM, Mil-Std, DIN 50 021, DIN EN ISO 9227

- All components installed inside the chamber are made from corrosion-resistant plastic

- Innovative WEBSeason® user interface offers simple programming and allows you to control and monitor your tests anytime, anywhere, from any device

Weiss Technik can develop a custom solution for your corrosion, salt spray applications. Our Application/Product Engineers can help find a solution for your exact testing requirement.