Specifications

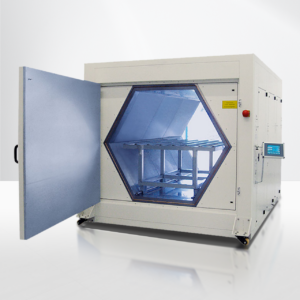

- Compliant with clean room class ISO 4 to ISO 7 requirements in accordance with DIN EN ISO 14644-1

- Ideal for clean rooms thanks to minimum footprint: our units can be placed space-saving directly next to one another

- Silicone-free version with Viton seal up to 450°C

- Oven version for combustible materials in accordance with EN 1539 or with explosion protection

- Gas-tight oven version for inert gas or hybrid processes

- Constant uniform spacial temperature distribution

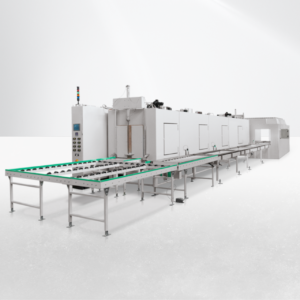

- Integration in automated production lines