Products

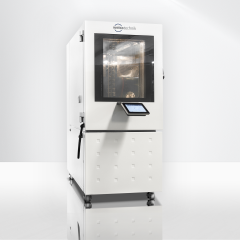

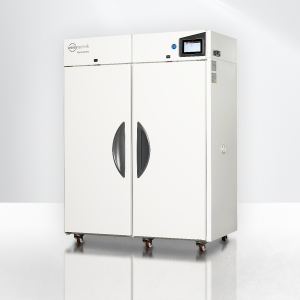

Environmental Test Chambers

Weiss Technik delivers the industry’s broadest portfolio of environmental test chambers, ranging from compact chambers for testing the smallest components to massive walk-in chambers capable of full vehicle testing. Our comprehensive range of climate test chambers features multiple patented technologies that simulate any environment from earth to space. With innovative solutions designed to increase product reliability, decrease warranty costs, and streamline product validation, our environmental testing systems future-proof your testing capabilities.

Our chambers incorporate innovative engineering and advanced technology. The quality construction, long-lasting durability and performance are unmatched in the industry. Future-proof chamber designs include environmental responsibility while offering customizable solutions for aerospace, automotive, electronics, pharmaceutical, and materials research applications.

Test Chamber Capabilities

- Custom-engineered solutions tailored to your unique test requirements, ensuring optimal performance for your specific testing protocols

- Combined environmental testing allows users to combine test conditions such as temperature, humidity, vibration and solar simulation to meet comprehensive performance testing requirements for complex applications

- Wide test ranges include temperatures from -70°C to +180°C, humidity from 10–98% RH, altitude up to 100,000 ft, vacuum and vibration

- Environmental chamber types such as temperature, humidity, altitude, vibration, thermal shock, corrosion, dust, water spray, thermal vacuum, and more

- Innovative control system WEBSeason® touchscreen interface & SIMPATI® software for remote test automation

- Sustainable, eco-conscious operation with LEEF Technology and Low-GWP refrigeration for energy savings and reduced carbon footprint

How do test chambers aid in product development and testing?

Environmental test chambers accelerate product development by simulating real-world conditions in controlled laboratory settings. They enable engineers to identify potential failures early in the design process, validate product performance across various environmental conditions, and ensure compliance with industry standards. This reduces development time, minimizes costly redesigns, and helps bring more reliable products to market faster. See our Environmental Test Chamber product locator to find the best test chamber for your needs.

What are environmental test chambers used to test?

Environmental test chambers are used to test a vast range of products and components across multiple industries. Common applications include electronic components, automotive parts, aerospace systems, pharmaceuticals, medical devices, textiles, packaging materials, and even full vehicles. These chambers can simulate temperature extremes, humidity variations, altitude changes, thermal cycling, and combined environmental stresses to evaluate how products perform under different conditions.

Why should you use test chambers?

Test chambers are essential for increasing product reliability, reducing warranty costs, and ensuring thorough product validation. They help identify weaknesses before products reach the market, enabling manufacturers to improve designs and materials. This proactive approach prevents costly field failures, protects brand reputation, and ensures compliance with regulatory requirements and industry standards.

What environmental conditions can Weiss Technik chambers simulate?

Our chambers can simulate an extensive range of environmental conditions including extreme temperatures and humidity levels, altitude changes, thermal shock, and combined environmental stresses. With our patented technologies, we can replicate virtually any environment from Earth to Space. Find the right chamber for your testing needs today, contact the Weiss Technik team.