Advanced Solutions for your Heat Technology & Production requirements

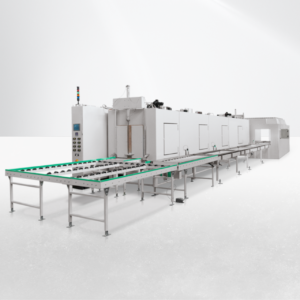

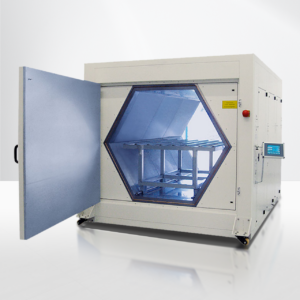

Weiss Technik’s complete portfolio of heating and drying ovens, tempering ovens, continuous ovens, production ovens and IR Infrared technology ovens provides advanced technology for your testing and production requirements. With advanced user and product safety features, our ovens meet many safety and industry requirements including EN 1539, and AMS 2750E or CQI-9. We have both pre-engineered and custom solutions.

Showing all 11 results

Industrial production heating ovens are a critical part of the production process. Heating and drying product ovens use a variety of applications such as high heat, tempering, drying, microwave, and IR infrared to achieve the correct physical, uniform, and chemical properties of the product.

Need something custom?

3881 N. Greenbrooke Dr. SE

Grand Rapids, MI 49512 USA

Phone: 616-554-5020

Toll-Free: 1-800-368-4768

Fax: 616-554-5021

© 2024 Weiss-Technik, All Rights Reserved